For several years, CHANGXIN have specialized in trading high-quality components in the field of industrial automation.

Focusing on PLC components, DCS and CNC technology, and drivetechnology

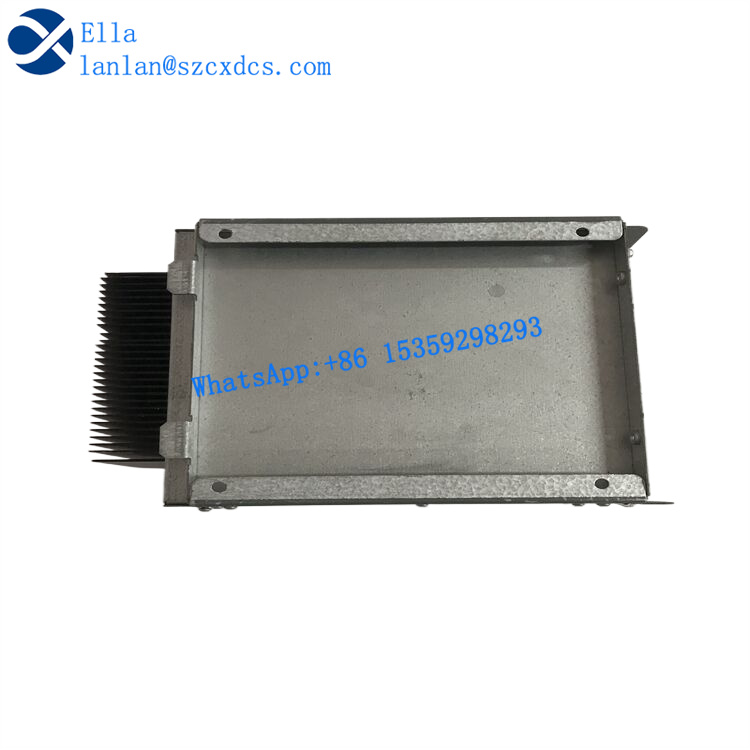

Bently Nevada 3500/06 protective box

| Brand: Bently |

| Part number: 3500/06 |

| Origin: United States |

| Minimum order quantity: 1 |

| Guarantee period: one year |

| Delivery time: 3-5 days after payment |

| Delivery methods: EMS, FedEx, Debon |

| Condition: In stock, brand new |

| Payment method: T/T, PayPal, Western Union remittance |

+86 15359298293

Bently Nevada 3500/05 System Framework Install all monitor modules

3500/06 System Features:

High Integration: The 3500 system can accommodate twice the number of channels in the same size frame space as previous monitoring systems, saving frame space and reducing installation costs.

Fault tolerance: The 3500 system can be configured with multiple levels of redundancy, including complete Triple Modular Redundancy (TMR) configuration, providing higher reliability and safety.

Self detection and fault-tolerant design: The system has self detection and fault-tolerant functions, which can identify faults in the monitor module and the sensors connected to it, and issue and confirm corresponding error codes.

Sliding bottom plate installation: allows the 3500 system to be installed on or near the machine’s sliding bottom plate, making the cables shorter and wiring costs lower.

3500/06 Product Application:

Widely used in power plants, refineries, chemical plants, steel plants, water pump plants, fan plants and other enterprise units.

Online measurement and protection of the shells of large rotating machinery shafts such as steam turbines, water turbines, blowers, compressors, air separators, gearboxes, and water pumps.

3500/06 Main Features:

Featuring self detection and fault-tolerant design, it can be configured with multiple redundancies, ranging from adding a second fully redundant power supply to a complete triple modular redundancy (TMR) configuration. It can be used for both selected channels and all channels, fully meeting the most critical task applications. The system can also provide continuous status monitoring information for proactive maintenance plan 1.

3500/06 Application Certification:

Design in accordance with the American Petroleum Institute standard API670; Complies with the API 618 standard for reciprocating compressor applications; And has passed DNV and ClassNK certification, as well as certifications from Canadian Standards Association (CSA), Factory Mutual Aid (FM), GOST, ATEX, and CE.

The 3500/06 protective box is a powerful and flexible online monitoring and protection system, suitable for situations that require continuous monitoring and protection of large rotating machinery. Its characteristics are high safety, high security, high precision, and durability.

Main business of the company

- ABB (DSQC, AC800M, OCS 07KT97/07AI/07DI, PM645, IGCT 5SHY/5SHX, etc.)

- Bentley (3500 3300 System Series)

- Honeywell (DC 2000, TDC3000, TPS, Security System)

- Schneider (Quantum 140 series: CPU processor, communication module)

- Foxboro(FBM203/2004/217, FCP240/270)

- EMERSON (DeltaV system, I/O unit, analog AI module, analog AO module)

- Motorola (VME 162, MVME 167, MVME1772, MVME177)

- YOKOGAWA (CS3000 system CPU controller module, analog module)

- EPRO (MMS6210/621, PR6423/003-031)