For several years, CHANGXIN have specialized in trading high-quality components in the field of industrial automation.

Focusing on PLC components, DCS and CNC technology, and drivetechnology

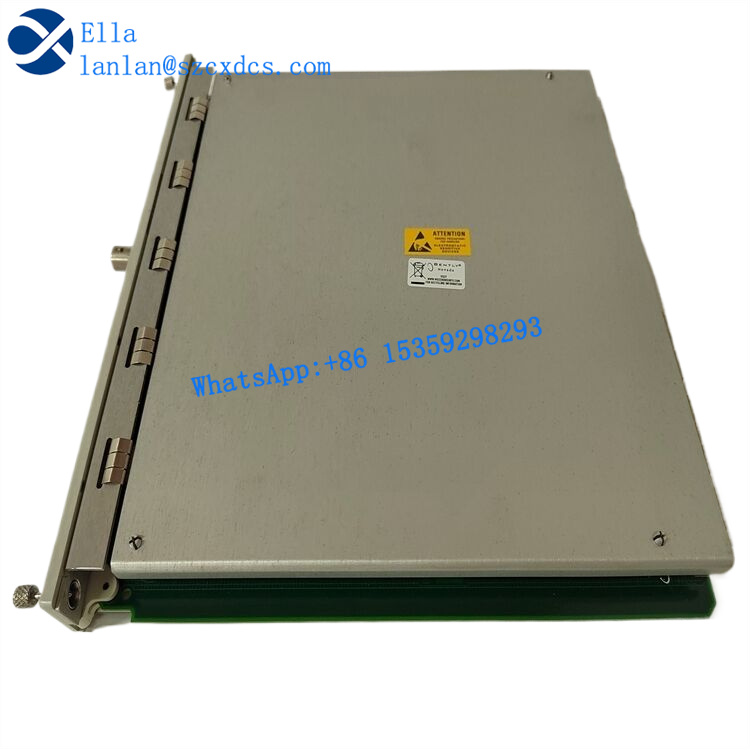

Bently Nevada 3500/53 Overspeed Detection Module

| Brand: Bently |

| Part number: 3500/53 |

| Origin: United States |

| Minimum order quantity: 1 |

| Guarantee period: one year |

| Delivery time: 3-5 days after payment |

| Delivery methods: EMS, FedEx, Debon |

| Condition: In stock, brand new |

| Payment method: T/T, PayPal, Western Union remittance |

+86 15359298293

Bently Nevada 3500/53 Overspeed Detection Module

Main functions and characteristics of 3500/53:

Overspeed protection: specifically designed for mechanical overspeed protection, aimed at driving alarms by continuously comparing the current machine speed with the configured alarm set point, achieving machine protection.

Quick response: The system provides a quick response function to ensure a quick response in the event of an overspeed event.

Redundant design: This module can form a 2 out of 2 or 3 out of 2 (recommended) voting system, improving the reliability and security of the system.

Multiple sensor support: suitable for Bently Nevada 3300 8mm eddy current sensors, 3300 16mm high-temperature eddy current sensors (HTPS), 7200 5mm, 8mm, 11mm, and 14mm eddy current sensors, 3300 RAM eddy current sensors, or magnetic sensors.

3500/53 Technical Specifications:

Input signal: Each overspeed detection module receives a signal from an eddy current sensor or magnetic sensor, with an input signal range of+10.0V to -24.0V. The signal exceeds this range and is restricted within the module.

Input impedance: 20k Ω.

Power consumption: Typically 8.0W.

Alarm Setpoint: For speed, it can be set below or above the alarm level (set point). In addition, dangerous (overspeed) setting points can be set for the rotational speed. All alarm setpoints are set by software configuration.

Alarm time delay: less than 30ms when the frequency is above 300Hz.

3500/53 System Configuration and Installation:

Installation requirements: The 3500 rack for installing the overspeed detection system requires redundant power supply.

Module location: The 3500/53 module can be installed in any slot (2-15) on the right side of the frame interface module, but the three module groups must be installed adjacent.

Configuration software: Use the 3500 rack configuration software to set alarm setpoints.

3500/53 application scenarios:

Industrial field: This module is widely used in key equipment monitoring in industries such as petrochemicals, power, steel, and papermaking, especially in situations where high-precision and high reliability overspeed protection is required.

Safety protection: Provide important machine speed information to operators and maintenance personnel, help identify potential problems in a timely manner, and take corresponding measures to ensure the safe operation of the equipment.

Main business of the company

- ABB (DSQC, AC800M, OCS 07KT97/07AI/07DI, PM645, IGCT 5SHY/5SHX, etc.)

- Bentley (3500 3300 System Series)

- Honeywell (DC 2000, TDC3000, TPS, Security System)

- Schneider (Quantum 140 series: CPU processor, communication module)

- Foxboro(FBM203/2004/217, FCP240/270)

- EMERSON (DeltaV system, I/O unit, analog AI module, analog AO module)

- Motorola (VME 162, MVME 167, MVME1772, MVME177)

- YOKOGAWA (CS3000 system CPU controller module, analog module)

- EPRO (MMS6210/621, PR6423/003-031)