For several years, CHANGXIN have specialized in trading high-quality components in the field of industrial automation.

Focusing on PLC components, DCS and CNC technology, and drivetechnology

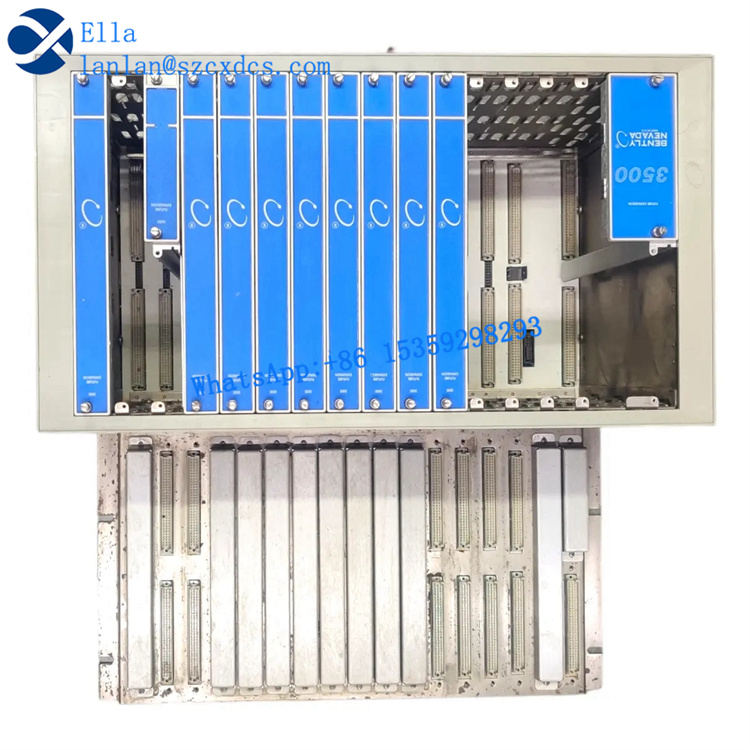

Bently Nevada 3500 Internal Barrier 3500/08 Fault Diagnosis Connection Panel

| Brand: Bently |

| Part number: 3500/08 |

| Origin: United States |

| Minimum order quantity: 1 |

| Guarantee period: one year |

| Delivery time: 3-5 days after payment |

| Delivery methods: EMS, FedEx, Debon |

| Condition: In stock, brand new |

| Payment method: T/T, PayPal, Western Union remittance |

+86 15359298293

Bently Nevada 3500 Internal Barrier 3500/08 Fault Diagnosis Connection Panel

3500/08 Overview

It is a critical component used in Bently Nevada 3500 series mechanical protection systems. This panel is designed for direct access to signals from the 3500/08 system without the need to open cabinet doors and without being affected by equipment conditions exposed to EMI/RFI or other harsh environments.

3500/08 Main Features

Direct access signal: Through the connection panel, users can directly access the dynamic data port of the 3500/08 system to obtain the required monitoring signals.

Easy installation and connection: The panel is connected to the 3500 system through a 4.6 meter (15 foot) signal cable, making installation and maintenance easier in environments that are difficult to access or require protection.

Strong compatibility: The panel not only supports direct connection, but also allows for the use of Y-shaped cables for multiple device connections. For example, the diagnostic access panel and external communication processor can be connected to the same dynamic port simultaneously.

3500/08 Technical Features

Shock resistance: The panel has good shock resistance and can operate stably in harsh industrial environments.

Environmental adaptability: The panel design takes into account the impact of harsh environmental factors such as EMI/RFI, and can provide stable signal transmission in these environments.

Modular design: The panel adopts a modular design, making maintenance and replacement more convenient and efficient.

3500/08 Fault Diagnosis Steps

When a malfunction occurs in the 3500/08 system, users can use the fault diagnosis connection panel for diagnosis by following the steps:

Check the LED status: Based on the display status of the LED lights, it is possible to preliminarily determine the operational status of the system.

Verification window information: View the system status and card output information through the Verification window to help quickly locate problems.

View system event list: When the LED lights indicate potential issues, you can view detailed information in the system event list and study the problems that have occurred.

Start monitor self-test: If you suspect there is a problem with the monitor, you can start the self-test program for further diagnosis.

3500/08 hardware composition

Interface: This panel can receive signals from six 3500 4-channel monitors and one 3500 2-channel Keyphasor module.

Connection method: Each channel has a coaxial connector, with a maximum cable length of 26 meters (85 feet).

3500/08 Operation Guide

Settings for connecting panels:

Connect the sensor: Connect the output terminals of the sensor to the corresponding coaxial connector.

Configuration parameters: Enter or modify the configuration parameters of the sensor on the panel to ensure its correct response to various situations in the mechanical protection system.

Collection and control:

Data collection: The panel will automatically collect data from sensors and store it in an internal database.

Fault diagnosis: When abnormal signals are detected, the panel will automatically trigger a fault diagnosis program to analyze and report possible problems.

Fault handling:

Fault recording: The panel will record all fault events and generate detailed fault reports.

Troubleshooting: Based on the fault report, operators can carry out targeted troubleshooting work.

System maintenance:

Regular inspection: Regularly inspect the connection panel and other related hardware to ensure that all components are working properly.

Software updates: Regularly check and install the latest software updates to ensure system stability and reliability.

Main business of the company

- ABB (DSQC, AC800M, OCS 07KT97/07AI/07DI, PM645, IGCT 5SHY/5SHX, etc.)

- Bentley (3500 3300 System Series)

- Honeywell (DC 2000, TDC3000, TPS, Security System)

- Schneider (Quantum 140 series: CPU processor, communication module)

- Foxboro(FBM203/2004/217, FCP240/270)

- EMERSON (DeltaV system, I/O unit, analog AI module, analog AO module)

- Motorola (VME 162, MVME 167, MVME1772, MVME177)

- YOKOGAWA (CS3000 system CPU controller module, analog module)

- EPRO (MMS6210/621, PR6423/003-031)